Introduction to 3 Phase Transformers

- Three-phase transformers are pivotal components in modern electrical systems, serving as the backbone for efficient power distribution across various industries. Unlike single-phase transformers, which handle power transmission in a single phase, three-phase transformers are designed to manage power transmission through three alternating currents that are out of phase with each other by 120 degrees. This configuration not only enhances the efficiency of power distribution but also ensures a more stable and reliable electricity supply.

- The primary function of a three-phase transformer is to step up (increase) or step down (decrease) voltage levels to meet the requirements of different stages in the power distribution network. For instance, electricity generated at power plants is typically at a high voltage and needs to be stepped down to a lower voltage suitable for industrial, commercial, and residential use. This voltage transformation is crucial for minimizing power losses over long distances, thereby optimizing the overall efficiency of the power distribution system.

- Three-phase transformers find applications in a multitude of sectors, including manufacturing, utilities, and transportation. In industrial settings, they are essential for powering heavy machinery and equipment that require a stable and robust power supply. Utilities rely on these transformers for efficient transmission of electricity from power generation stations to end-users. Moreover, in public transportation systems, such as railways and subways, three-phase transformers ensure the smooth operation of electrical locomotives and other electrically powered infrastructure.

- Testing three-phase transformers is paramount for several reasons. First and foremost, regular testing helps in identifying any potential faults or inefficiencies that could compromise the transformer’s performance. Ensuring that transformers operate efficiently is vital for maintaining the reliability of the electrical grid. Additionally, safety is a significant concern; transformers are subject to high electrical loads and thermal stresses, which, if unchecked, could lead to hazardous conditions such as short circuits or fires. Therefore, routine testing is essential for preventing malfunctions and ensuring the safe operation of electrical systems.

- Three-phase transformers are indispensable in modern electrical systems, performing critical roles in power distribution and industrial applications. Understanding their structure, function, and the importance of regular testing is crucial for anyone involved in electrical engineering and maintenance.

Pre-Testing Preparations

- Before embarking on any tests on a 3 phase transformer, it is crucial to undertake meticulous pre-testing preparations. These steps not only ensure the accuracy of the tests but also uphold safety standards. The first essential step is to thoroughly consult the transformer’s manual. This document offers indispensable information, including specific procedures, safety guidelines, and technical specifications unique to the transformer model.

- Equipping yourself with the necessary tools and equipment is the next pivotal step. Basic tools such as a multimeter, insulation resistance tester, and a megger are indispensable. Additionally, ensure that you have personal protective equipment (PPE) such as insulated gloves, safety goggles, and appropriate footwear to mitigate the risk of electrical hazards.

- De-energizing the transformer is a fundamental safety measure. This involves disconnecting the transformer from the power source and ensuring that all residual energy is discharged. Grounding procedures are critical at this stage to prevent any accidental energization. Grounding ensures that the transformer and its components are at the same potential, drastically reducing the risk of electric shock.

- Another important step is to perform a thorough visual inspection of the transformer. Check for any visible damages or issues such as oil leaks, corrosion, or loose connections. These visual checks can often preempt potential problems that might arise during testing.

- Recording initial data is an essential part of the pre-testing process. Documenting baseline readings such as voltage levels, current, and resistance values provides a reference point for future tests and helps in identifying any deviations or anomalies.

- Finally, setting up a clean and safe work environment cannot be overstressed. Ensure that the testing area is free from any clutter, moisture, or conductive materials that could pose safety hazards. A well-organized workspace not only enhances safety but also improves the efficiency and accuracy of the testing process.

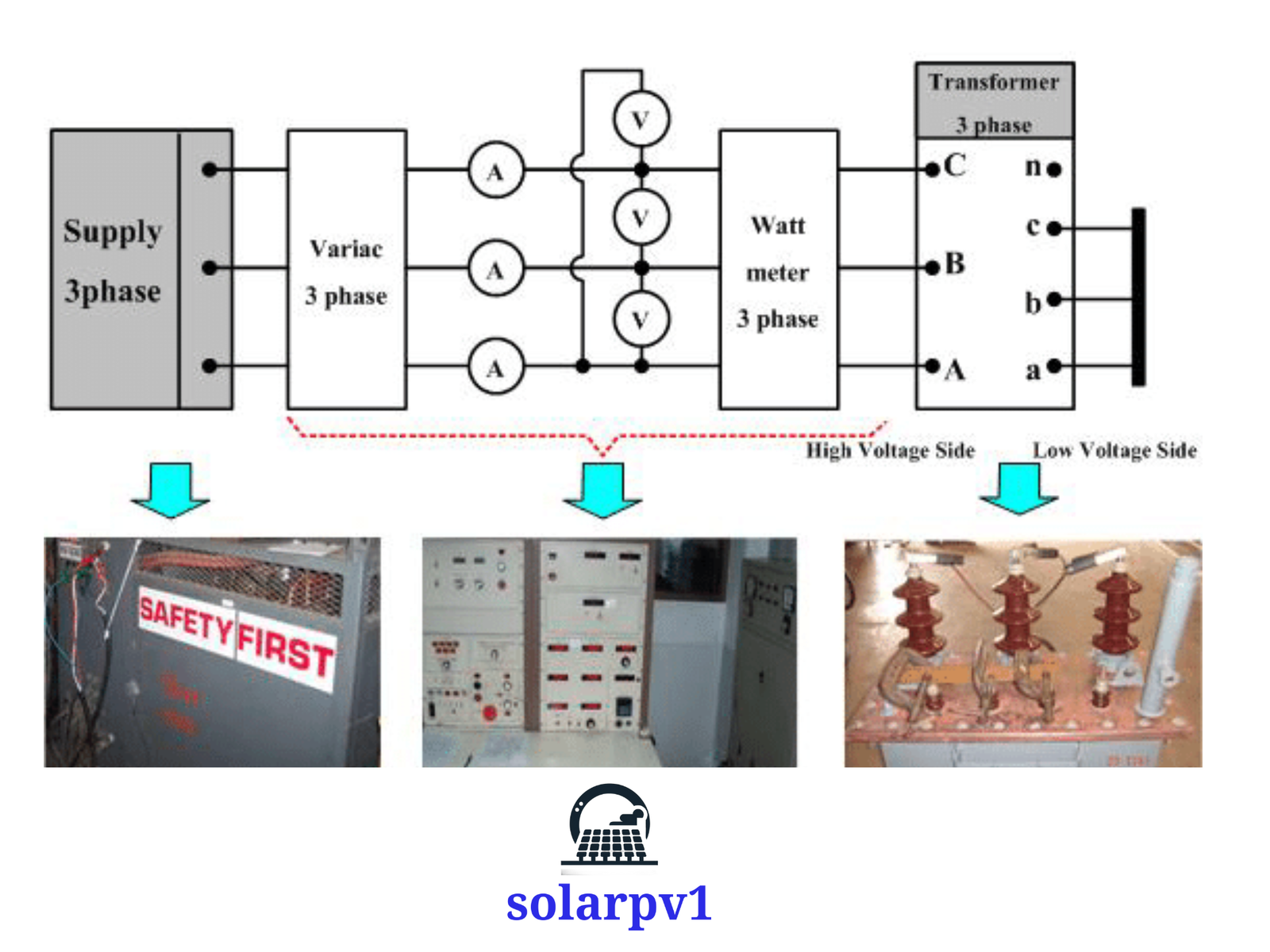

Primary Methods for Testing

Testing a 3 phase transformer is crucial for ensuring its operational efficiency and longevity. The primary methods used include insulation resistance testing, transformer turns ratio (TTR) testing, and power factor testing. Each of these tests serves a distinct purpose and requires specific equipment and procedures.

Insulation Resistance Testing: This test measures the resistance of the transformer’s insulation to detect any deterioration or faults. The purpose is to ensure the insulation is effective in preventing electrical leakage. A megohmmeter is used for this test. To conduct the test, connect the megohmmeter leads to the transformer’s windings and ground. Apply the recommended test voltage and record the resistance values. Compare these values against industry standards like those from IEEE or IEC. Low resistance may indicate moisture or insulation breakdown, necessitating further investigation or maintenance.

Transformer Turns Ratio (TTR) Testing: TTR testing verifies the turns ratio of the transformer windings, which is essential for its correct operation. A TTR tester is utilized for this purpose. To perform the test, connect the tester to the primary and secondary windings of the transformer. The device will apply a low voltage to the primary winding and measure the resulting voltage on the secondary winding. The ratio of these voltages should match the transformer’s specified ratio. Deviations may indicate winding damage or incorrect connections.

Power Factor Testing: This test assesses the transformer’s insulation condition by measuring the power factor, which is the ratio of real power to apparent power. A power factor tester is required. Connect the tester to the transformer and apply the specified test voltage. The resultant power factor value should be low; high values suggest insulation degradation. Regular power factor testing helps in early detection of potential issues, allowing for timely maintenance.

During testing, it is essential to follow industry standards such as those outlined by IEEE, NETA, and IEC. These guidelines ensure the accuracy and safety of the tests. Common issues that might arise include incorrect test setup, environmental factors affecting readings, and equipment malfunctions. Proper training and adherence to procedural guidelines can mitigate these issues, ensuring reliable test results.

Analyzing Test Results and Troubleshooting

- Upon completing the various tests on a 3 phase transformer, analyzing the obtained results is crucial for ensuring optimal performance and detecting potential issues. Normal readings for transformer tests typically include balanced voltage and current values across all phases, minimal insulation resistance, and consistent power factor and efficiency metrics. Abnormal readings, on the other hand, can be indicative of underlying problems that may require immediate attention.

- For instance, if the insulation resistance test reveals significantly lower resistance than expected, it could indicate insulation degradation or moisture ingress, which can compromise the transformer’s operational integrity. Similarly, unbalanced voltage or current values across the phases during the turns ratio test might suggest winding defects or connection issues.

- When abnormal readings are detected, troubleshooting steps should be systematically undertaken. Begin by verifying the accuracy of the test equipment and re-conducting the tests to rule out any errors. If the results remain consistent, proceed to inspect the transformer for visible signs of damage such as burnt components, oil leaks, or unusual noises during operation.

- Common problems identified during testing include overheating, which can be traced back to overloading or poor ventilation, and partial discharges often caused by insulation failures. Once the specific issue is pinpointed, appropriate follow-up actions should be implemented. These may range from conducting repairs, such as replacing damaged insulation or tightening loose connections, to scheduling further diagnostic tests like dielectric frequency response analysis.

- In some cases, it may be more cost-effective to replace the transformer rather than attempting extensive repairs. For example, a case study involving a manufacturing plant revealed that replacing an aged transformer with recurrent insulation failures significantly improved operational reliability and reduced downtime.

- In conclusion, diligent analysis of test results and prompt troubleshooting are essential in maintaining the efficiency and longevity of 3 phase transformers. Adhering to these practices not only ensures safe and reliable operation but also helps in timely detection and resolution of potential issues.