Introduction Current Transformer Rating

- Current transformers (CTs) are essential components in electrical systems, playing a critical role in the measurement and monitoring of electrical currents. These devices are specifically designed to step down high voltage currents to a safer, more manageable level, facilitating accurate measurement and analysis. By converting high currents into a lower, standardized current, CTs ensure that monitoring equipment can function correctly without being exposed to the potentially damaging effects of high voltage.

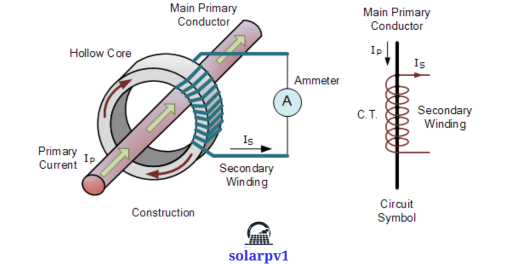

- The primary function of a current transformer is to provide a scaled-down current that is proportional to the current flowing in the high voltage circuit. This is achieved through electromagnetic induction, where the CT’s primary winding is connected in series with the high voltage line, and the secondary winding is connected to the measuring or monitoring device. This setup allows for the precise measurement of current without the need to directly interface with the high voltage circuit, thereby enhancing safety and efficiency.

- Current transformers are indispensable in various applications, including power generation, transmission, and distribution. They are also widely used in industrial environments where accurate current measurement is crucial for both operational monitoring and system protection. The ability to monitor high voltage currents accurately ensures that electrical systems can be managed more effectively, reducing the risk of overloading and potential faults.

- There are several types of current transformers available in the market, each designed for specific applications. Some of the most common types include wound, toroidal, and bar-type CTs. Wound current transformers have a primary winding that is physically wound around the core, making them suitable for low to medium voltage applications. Toroidal current transformers, on the other hand, do not have a primary winding and are typically used for high accuracy measurements in systems with higher voltage levels. Bar-type CTs, which utilize a straight conductor as the primary winding, are commonly used in high current applications due to their robust design.

- In summary, current transformers are pivotal in ensuring the safe and accurate measurement of electrical currents in high voltage systems. By understanding their function and the different types available, industry professionals can make informed decisions about their use in various applications, thereby optimizing the performance and safety of electrical systems.

Key Parameters of Current Transformer Ratings

Understanding the key parameters that define the rating of a current transformer (CT) is essential for selecting the right device for any application. These parameters include primary and secondary current ratings, rated burden, accuracy class, and rated voltage. Each of these elements plays a crucial role in determining the performance and suitability of a current transformer.

Primary and Secondary Current Ratings: The primary current rating refers to the maximum current that can flow through the primary winding of the CT without causing damage or excessive heating. This rating is crucial as it ensures the CT can handle the expected load current. Conversely, the secondary current rating is the current that the secondary winding will produce when the primary current is at its rated value. Typically, secondary currents are standardized to 1A or 5A.

Rated Burden: The rated burden of a current transformer is the load that the CT can drive while maintaining its accuracy. It is expressed in volt-amperes (VA) and represents the total impedance of the devices connected to the secondary winding, such as meters and relays. Selecting a CT with an appropriate rated burden ensures accurate measurements and reliable protection.

Accuracy Class: This parameter indicates the accuracy of the current transformer in representing the actual primary current. Accuracy classes are defined by standards such as IEC or ANSI and are typically expressed as a percentage. For instance, a CT with an accuracy class of 0.5 has an error margin of ±0.5% under specified conditions. Higher accuracy classes are critical for precise measurements and protective relays.

Rated Voltage: The rated voltage of a CT is the maximum voltage that can be applied to its secondary winding without causing insulation breakdown. This rating ensures the CT can operate safely within the electrical system’s voltage levels. It is particularly important in high-voltage applications where insulation performance is critical.

In practical scenarios, these ratings help engineers select the appropriate current transformer for specific applications. For example, in a high-voltage substation, a CT with a high primary current rating, accurate class, and suitable rated burden ensures reliable monitoring and protection. Understanding these parameters enables the selection of a CT that meets the system’s requirements, ensuring optimal performance and safety.

Factors Influencing Current Transformer Rating Selection

- Choosing the appropriate current transformer (CT) rating is crucial for ensuring optimal performance and safety in electrical systems. Several key factors need to be considered, including load capacity, system voltage, environmental conditions, and the required accuracy level. Understanding and matching these factors with the CT ratings will help in achieving the desired outcomes effectively.

- Firstly, load capacity is a fundamental consideration. The CT must handle the maximum load current without saturation. Overloading a CT can lead to inaccurate measurements, posing risks to system integrity. It is recommended to select a CT with a rating that exceeds the maximum expected load by a safe margin to account for potential surges and future load increases.

- System voltage is another critical factor. The insulation level of the CT must be compatible with the system’s voltage. In high-voltage applications, special attention must be given to the insulation class to prevent breakdowns. Ensuring that the CT’s primary insulation can withstand voltage fluctuations is essential for maintaining system reliability.

- Environmental conditions also play a significant role in CT rating selection. Factors such as temperature, humidity, and exposure to corrosive elements can affect a transformer’s performance. For instance, in high-temperature environments, CTs with enhanced thermal performance and protective enclosures may be required. Similarly, in corrosive atmospheres, CTs with robust material construction and protective coatings are necessary to resist degradation.

- The required accuracy level is another vital aspect. Precision is paramount, particularly in metering and protection applications. CTs are classified into different accuracy classes, and the selection should align with the application’s sensitivity requirements. For protection purposes, a lower accuracy class may suffice, whereas metering applications typically demand higher accuracy to ensure billing precision.

- To illustrate, consider a power plant requiring CTs for both metering and protection. The metering CTs would need a higher accuracy class, such as 0.2 or 0.5, to ensure precise energy measurements. Conversely, protection CTs might use a 5P or 10P accuracy class to provide reliable fault detection without necessitating extreme precision. Selecting CTs with appropriate ratings for diverse applications within the same system underscores the importance of tailored solutions.

- By carefully evaluating these factors—load capacity, system voltage, environmental conditions, and accuracy level—engineers can ensure that the selected CT ratings align with the specific demands of the application, thereby enhancing system performance and safety.

Common Challenges and Best Practices in Using Current Transformers

- Using current transformers (CTs) presents several challenges that can impact their performance and accuracy. One of the primary issues is saturation, which occurs when the magnetic core of the transformer becomes fully magnetized. This can lead to inaccurate current readings and potential damage to the transformer. To mitigate saturation, it’s essential to select a CT with a suitable rating for the intended application and to avoid overloading the transformer.

- Thermal issues are another common challenge. Excessive heat can degrade the insulation and other components of a CT, leading to failures. Proper ventilation and cooling measures should be implemented during installation to prevent overheating. Additionally, it’s crucial to ensure that CTs are not exposed to temperatures beyond their specified operating range.

- Signal distortion can also affect the accuracy of current transformers. This distortion can arise from various sources, including electrical noise and harmonics in the system. Using shielded cables and ensuring proper grounding can help reduce these interferences. Furthermore, selecting CTs with low distortion characteristics can enhance measurement accuracy.

- Adhering to best practices in installation, maintenance, and troubleshooting is vital for the optimal performance of current transformers. Correct installation involves placing the CTs in the appropriate orientation and ensuring secure connections. Regular maintenance, including visual inspections and cleaning, can help identify and address potential issues before they escalate. Troubleshooting should involve checking for signs of wear, loose connections, and any abnormalities in the readings.

- Regular calibration and testing are crucial for maintaining the accuracy and reliability of current transformers over time. Calibration should be performed according to the manufacturer’s guidelines and industry standards. Periodic testing can help detect any deviations in performance and ensure that the CTs continue to operate within their specified parameters.

- For those seeking further knowledge, consulting with experts and accessing resources such as technical manuals and industry publications can be invaluable. Staying informed about the latest advancements and best practices in the field can help users effectively manage the challenges associated with current transformers and optimize their performance in various applications.