Introduction to Transformer Testing

- Transformers are integral components of electrical power systems, serving as devices that transfer electrical energy between two or more circuits through electromagnetic induction. Their primary purpose is to step up (increase) or step down (decrease) voltage levels, facilitating efficient power distribution across vast distances. Ensuring the reliability, efficiency, and safety of transformers is paramount, as their failure can result in significant power outages, economic losses, and safety hazards.

- Transformer testing is essential for maintaining the performance and longevity of these critical assets. Regular testing helps detect potential issues before they escalate into major problems, ensuring that transformers operate within acceptable parameters. By identifying faults early, maintenance teams can implement corrective measures promptly, thereby minimizing downtime and extending the lifespan of the equipment.

- There are various types of transformers, each serving a unique function within the power system. Power transformers are used in transmission networks to transfer high-voltage electricity from power plants to substations. Distribution transformers, on the other hand, are found in distribution networks, stepping down the voltage for end-user consumption. Instrument transformers, including current transformers and voltage transformers, are used for measurement and protection purposes, providing accurate readings and isolating measurement devices from high voltages.

- To ensure that transformers meet operational standards and perform optimally, several testing methods are employed. These tests can be broadly categorized into routine tests, type tests, and special tests. Routine tests are performed on all transformers to verify their compliance with specified standards. Type tests are conducted on prototype units to ensure they meet design specifications, while special tests are tailored to address specific concerns or requirements.

- In the following sections, we will delve into the various transformer testing methods, examining their objectives, procedures, and significance. These insights will equip industry professionals with the knowledge needed to maintain and enhance the reliability of transformer operations within the electrical power system.

-

Transformer Testing

Electrical Tests for Transformers

Electrical tests are paramount in ensuring the performance and reliability of transformers. These tests aim to detect faults, assess the operational integrity, and prevent potential failures. Among the crucial tests are insulation resistance testing, turns ratio testing, winding resistance testing, and dielectric tests.

- Insulation Resistance Testing is one of the fundamental tests performed on transformers. It measures the resistance of the insulation between the transformer windings and earth or between different windings. This test employs a megohmmeter to apply a high DC voltage, typically between 500V and 5kV, across the insulation. The primary objective is to identify any degradation in the insulation material, which can lead to short circuits or reduced efficiency. A higher resistance value generally indicates better insulation quality.

- Turns Ratio Testing ensures the correct ratio between the primary and secondary windings, which is crucial for the transformer’s proper operation. This test uses a turns ratio tester to apply a voltage to the primary winding and measure the resulting voltage in the secondary winding. The measured ratio is then compared to the transformer’s specified ratio. Discrepancies can indicate issues like shorted turns or incorrect winding connections.

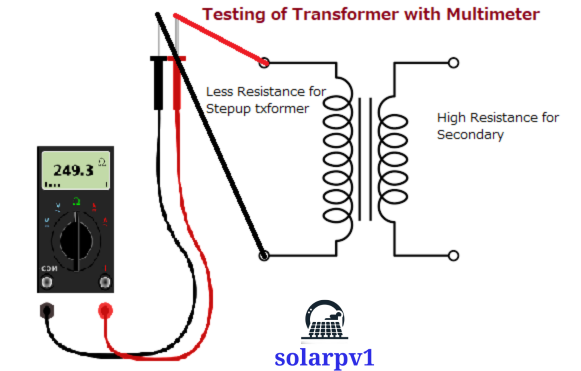

- Winding Resistance Testing measures the resistance of the transformer windings. This test is conducted using a micro-ohmmeter to inject a small DC current into the windings and measure the voltage drop. The winding resistance values provide insight into the condition of the windings and connectors. Significant deviations from the expected resistance can signal problems such as loose connections, broken strands, or issues with the tap changer.

- Dielectric Tests are crucial for assessing the insulation system’s strength. These tests include the Power Factor Test and the Insulation Power Factor Test. They measure the dielectric loss and the overall effectiveness of the insulation. A high power factor indicates poor insulation, which can lead to energy losses and overheating. These tests often require specialized equipment such as a power factor test set.

- The importance of these electrical tests cannot be overstated. They play a critical role in identifying potential issues before they escalate, ensuring the transformer’s operational integrity, and extending its service life. Regular testing and maintenance are essential for reliable and efficient transformer operation.

Mechanical and Thermal Testing

- Mechanical and thermal testing are critical components in ensuring the reliability and longevity of transformers. These tests help in identifying structural weaknesses and thermal inefficiencies, which are crucial for maintaining operational safety and performance.

- Mechanical tests, such as short-circuit tests and vibration analysis, are essential in assessing the structural integrity of transformers. Short-circuit tests simulate the conditions that a transformer might experience during a fault, ensuring that it can withstand such stresses without sustaining damage. This test involves subjecting the transformer to high currents and observing its performance and behavior. Vibration analysis, on the other hand, helps in detecting any mechanical imbalances or structural flaws that may lead to failures. By monitoring the vibrations, engineers can pinpoint issues such as loose components, misalignments, or other mechanical defects.

- Thermal testing is equally important as it focuses on the thermal performance of transformers. Temperature rise tests are conducted to measure the temperature increase in various parts of the transformer when it operates under load. This test helps in determining the thermal limits and ensuring that the transformer does not overheat during normal operation. Excessive temperatures can lead to insulation degradation and, ultimately, transformer failure.

- Thermal imaging, another vital aspect of thermal testing, involves using infrared cameras to detect hot spots and temperature anomalies. This non-invasive method allows for real-time monitoring of the transformer’s thermal condition, enabling early detection of overheating issues. By identifying and addressing these hot spots promptly, maintenance teams can prevent potential failures and extend the transformer’s service life.

- The procedures for these tests typically involve specialized equipment and trained personnel. Short-circuit tests require high-current generators and precise measuring instruments, while vibration analysis utilizes accelerometers and data acquisition systems. Thermal tests, such as temperature rise tests and thermal imaging, necessitate the use of thermocouples, infrared cameras, and data loggers.

- Overall, mechanical and thermal testing provides valuable insights into the condition of transformers, helping to ensure their safe and efficient operation. By conducting these tests regularly, operators can identify and mitigate potential issues, enhancing the reliability and longevity of their electrical infrastructure.

Advanced Diagnostic Techniques

- Advanced diagnostic techniques are crucial for the comprehensive assessment of transformer health and functionality. One of the most prominent methods is Dissolved Gas Analysis (DGA). DGA involves sampling the insulating oil within the transformer and analyzing the dissolved gases. Specific gas concentrations and their relative proportions can indicate various fault types, such as overheating, partial discharges, and arcing. By identifying these gases early, predictive maintenance can be effectively planned, mitigating the risk of catastrophic failures.

- Another essential technique is Frequency Response Analysis (FRA). FRA is employed to detect mechanical integrity issues within the transformer. It works by injecting a range of frequencies into the transformer and analyzing the output response. Variations in the response can reveal deformations or displacements in the winding structure, core, or other internal components. This method is particularly valuable for detecting issues following transport or after events like short circuits.

- Partial Discharge (PD) measurement is another critical diagnostic tool. PD refers to small electrical discharges that occur within the insulation system of the transformer. Over time, these discharges can degrade the insulation, leading to significant faults. PD measurement techniques can detect these discharges, allowing for early intervention and maintenance planning. This method is highly effective in identifying insulation deterioration and preventing unexpected transformer failures.

- Sweep Frequency Response Analysis (SFRA) is similar to FRA but utilizes a broader frequency range. SFRA is particularly effective at detecting physical changes within the transformer, such as winding deformation, core movement, and other mechanical issues. By comparing the frequency response signature over time or against a baseline, engineers can identify and address potential problems before they escalate.

- These advanced diagnostic techniques play a pivotal role in the predictive maintenance and overall health assessment of transformers. They enable utilities and industries to detect and rectify issues early, enhancing the reliability and longevity of these critical assets. Real-world applications have shown the effectiveness of these methods, with numerous case studies highlighting their role in preventing transformer failures and optimizing maintenance schedules.