Testing and commissioning of a circuit breaker

Purpose

procedure is prepared to carry out various pre-commissioning tests to be conducted in a systematic dmanner for Circuit Breaker to ensure the healthiness and performance of the equipment

Scope

This procedure covers the Pre commissioning test for Circuit Breaker as for the following

- Insulation resistance of control circuit

- Coil measurement

- DEW point test

- CRM Test

- Timing Test

- Insulation Resistance Test for circuit breaker

Pre-Testing Checks

- Check out the working condition of ELCB(30 mA)

- Check the insulation of power cable for equipment

- Ensure proper earthing and rubber mats available at the work location.

- Calibrated Testing equipment should be used and calibration reports available with engineers for the same

- Check out the insulates hand tools available with the technician

- Ensure the Healthiness of the test leads (Check for any insulation Damages)

- Ensure appropriate PPE’s available at sites

Resources – Tools and Equipment Required

- For IR for control circuit:

- Insulation tester

- Connecting leads

- Coil measurement:

- Multimeter

- Single three pole meter

- Connecting leads

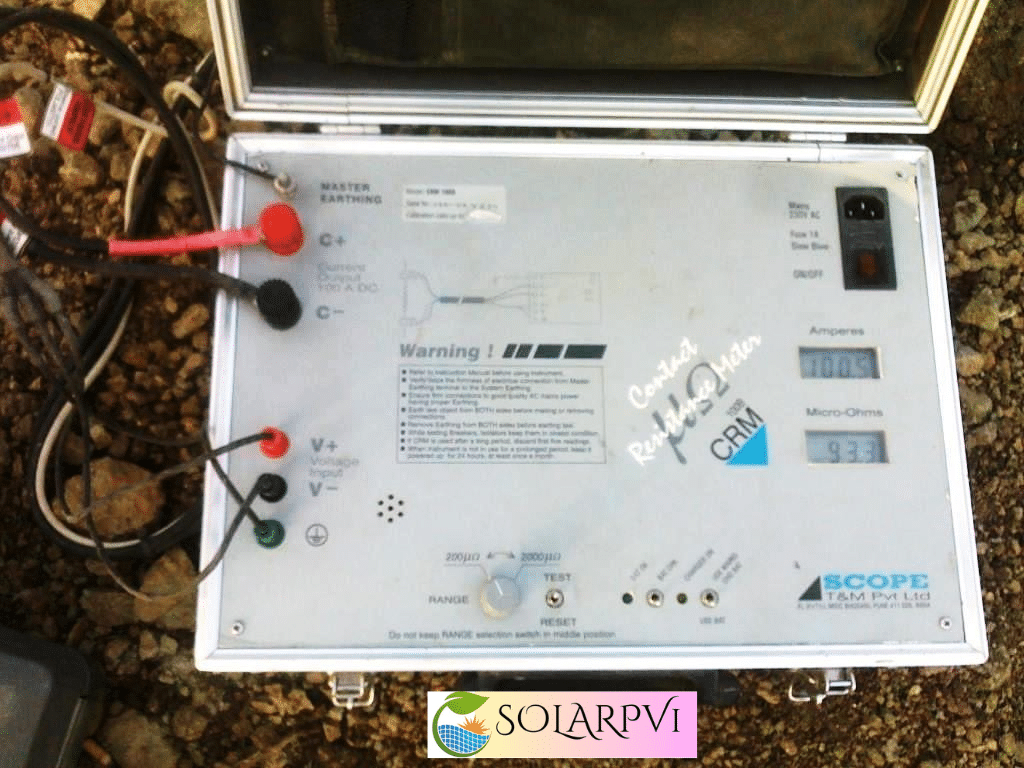

- For CRM Test:

- CRM kit

- Connecting Leads

- Multimeter

- For DEW point:

- Dew point kit

- For Timing Test and coil resistance measurement for circuit breaker:

- Timer Kit

- Test Leads

- Multimeter

- For Insulation Resistance measurement for circuit breaker & control circuit (IR Test):

- Test Leads

- 500 V, 5000 V Insulation Tester

- Insulated Hand Tools

- Multimeter

Operational Sequence of work(Test Procedure)

- Obtain the work permit from the client

- Ensure zero energy in the Circuit Breaker

- Ensure the all connections are in tight before testing

Insulation resistance for control circuit

Control circuit of breakers

- Connect the IR kit across the various points of the control circuit

- Switch ON the IR kit

- Note down the readings

Main circuitof breakers (pole)

- Connect the IR kit across the interrupter while circuit breaker Open condition

- Connect the IR kit across the Pole & Earth while circuit breaker on Close condition

- Switch ON the IR kit

- Note down the readings

Coil Measurement:

TRIP COIL / CLOSE COIL RESISTANCE MEASUREMENT TEST

- Select the Multi meter in Resistance Mode.

- Connect the Multi meter across the Trip/Close coils.

- Note down the readings

OPENING / CLOSING TIME MEASUREMENT TEST

- Connect the Timer across the Breaks for the Opening Time

- Connect the Timer across the Pole for the Closing Time/ “Close-Open” Time

Dew point test:

- Keep breaker off condition

- Connect dew point kit inlet valve to breaker

- Keep outlet valve open condition

- Note down the readings from dew point kit

Contact Resistance Measurement Test:

- Keep the Breaker in closed condition

- Connect the earth from CRM kit to earth plate or earth pit

- Connect the CRM kit Current Leads(C+ & C-) across the RØ Circuit Breaker contact

- Then Connect the CRM kit Voltage leads (V+ & V-) across the RØ Circuit Breaker contact. Voltage leads should be connect inside the Current leads

- Connect the CRM kit in A.C supply extension board with ELCB rated with 30 mA

- Inject the rated current to the Circuit Breaker

- Note down the contact resistance value from the CRM kit

- Repeat the above steps for the other phases (YØ & BØ)

- Switch off the power supply to the CRM Kit and disconnect them

| DO’s | DON’TS |

|

|

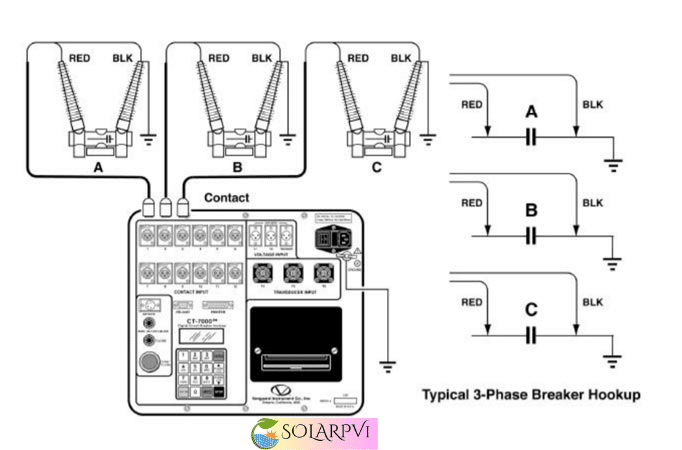

Timing Test:

- Keep the Breaker in closed condition

- Connect the earth from Timer kit to earth plate or earth pit

- Connect the Timer kit feedback cables R and R’ leads across the RØ Breaker contact

- Connect the Timer kit feedback cables Y and Y’ leads across the YØ Breaker contact

- Connect the Timer kit feedback cables B and B’ leads across the BØ Breaker contact

- Connect the Timer kit in A.C supply extension board with ELCB rated with 30 mA

- Give The open command and note down the value from the timer kit

- Give the close command and note the value from the timer Kit

- Give the close/open command and note the value from the timer kit

- Switch off the power supply to the Timer Kit and disconnect them

| DO’s | DON’TS |

|

|

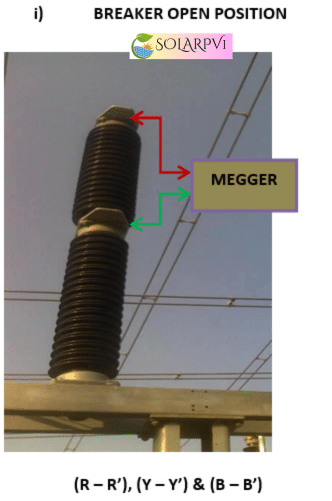

Insulation resistance

IR TEST (BREAKER OPEN CONDITION)

- Keep the Circuit Breaker in open position

- Connect the 5000 V IR kit across the RØ Breaker contact (R & R’)

- Select the required voltage range in 5000 V IR kit

- Switch ON the 5000 V IR kit and press the test button take down the reading

- Repeat the above steps for the other phases (YØ & BØ)

- Discharge the voltage from the Circuit Breaker with respect to earth.

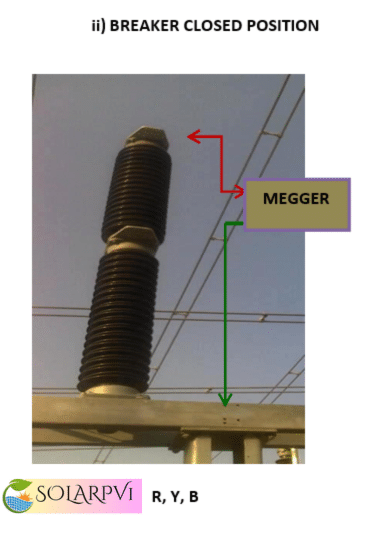

IR TEST BETWEEN PHASE TO EARTH (BREAKER CLOSED CONDITION)

- Keep the Circuit Breaker in closed position

- Connect the 5000 V IR kit Positive lead with RØ Breaker contact

- Connect the 5000 V IR kit Negative lead with earth

- Select the required voltage range in 5000 V IR kit

- Switch ON the 5000 V IR kit and press the test button take down the reading

- Repeat the above steps for the other phases (YØ & BØ)

- Discharge the voltage from the Circuit Breaker with respect to earth.

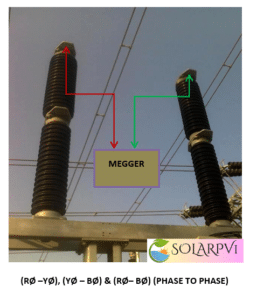

IR TEST BETWEEN PHASE TO PHASE (BREAKER CLOSED POSITION):

- Keep the Circuit Breaker in closed position

- Connect the 5000 V IR kitPositive lead with RØ Breaker contact

- Connect the 5000 V IR kit Negative lead with BØ Breaker contact

- Select the required voltage range in 5000 V IR kit

- Switch ON the 5000 V IR kit and press the test button take down the reading

- Repeat the above steps for the other phases to phase (RØ-YØ), (YØ & BØ) & (RØ-BØ)

- Discharge the voltage from the Circuit Breaker with respect to earth.

| DO’S | DON’TS |

|

|

Control Measures

- OCP for CRM, Timing and IR test for Circuit Breaker is available with testing engineers

- Ensure PTW system in place for the particular bay

- Ensure all supply to the equipment is dead

- Unauthorized persons should not be allowed to enter Testing area

- Barricade the testing area with warning tape

- More than 2Mtr height shall be used safety belt or full body hardnessand proper working plat form or man lifter

- Less than 2Mtr height shall be used standard insulated ladder

- Inspect the ladders prior to work, keep both feet below 3rd rung from top, keep one hand on ladder minimum at all times.

- Proper supervision, conduct job specific toolbox meeting and barricading the entire area

- Calibrated equipment shall be used

- Insulated hand tools shall be used

- Avoid joints for power cable and supply has to be taken via ELCB

- Avoid Lone working

- Use appropriate insulated hand gloves