Introduction to Transformers, CT and Normal Transformer

- Transformers are fundamental components in electrical systems, playing a crucial role in the transmission and distribution of electrical power. At their core, transformers operate based on the principle of electromagnetic induction, a process where a changing magnetic field induces an electrical current in a conductor. This principle is harnessed within two key parts of a transformer: the primary winding and the secondary winding. The primary winding is connected to the input voltage source, while the secondary winding delivers the transformed voltage to the load.

- Transformers are indispensable in voltage regulation, allowing for the adjustment of voltage levels to suit specific applications, from high-voltage power transmission to low-voltage distribution for residential use. Moreover, they provide electrical isolation, ensuring safety and reducing the risk of electric shocks.

- There are several types of transformers, each designed to meet specific needs. The most common ones include power transformers, distribution transformers, isolation transformers, and autotransformers. Power transformers are used in high-voltage transmission networks, while distribution transformers step down the voltage for consumer use. Isolation transformers provide galvanic isolation, protecting devices from electrical noise and surges. Autotransformers, on the other hand, use a single winding to adjust voltage levels with a higher efficiency.

- Among these diverse types, two specific categories warrant particular attention: current transformers (CT) and normal transformers. Normal transformers, also known as voltage transformers, primarily manage voltage levels. Current transformers, conversely, are specialized devices designed to measure and monitor electrical currents. They play a pivotal role in power system protection and metering, ensuring the accurate measurement of current flow in high-voltage circuits without the need for direct contact.

- Understanding the fundamental operation and types of transformers sets the stage for a comprehensive exploration of the distinct characteristics and applications of current transformers and normal transformers, highlighting their unique functions and significance in various electrical systems.

Understanding Normal Transformers

- Normal transformers, often referred to simply as transformers, are pivotal components in electrical power distribution and various industrial applications. Their primary function is to alter voltage levels, either stepping up or stepping down the voltage to suit specific needs. This ability to modify voltage is essential for efficient power transmission over long distances and for safe utilization in homes and businesses.

- The design of a normal transformer comprises several key components. The core, typically made of laminated silicon steel, serves to reduce energy losses due to hysteresis and eddy currents. The windings, usually copper or aluminum, are coiled around the core and are responsible for inducing electromagnetic fields that facilitate the voltage transformation process. Insulation materials, such as paper, oil, or solid insulation, are employed to prevent short circuits and ensure operational safety.

- Normal transformers are classified based on their ratings and specifications. Power rating, expressed in kilovolt-amperes (kVA), indicates the maximum amount of energy the transformer can handle. Efficiency, which is the ratio of output power to input power, is a critical parameter as it impacts energy losses and operational costs. Operational frequency, typically 50 Hz or 60 Hz depending on the region, is another important specification that aligns with the standard power grid frequency.

- The primary applications of normal transformers include voltage regulation in power distribution systems. Step-up transformers increase voltage levels, making it feasible to transmit electricity over long distances with minimal losses. Conversely, step-down transformers reduce voltage levels for safe distribution to residential, commercial, and industrial consumers. Beyond power distribution, normal transformers are also used in various industries such as manufacturing, mining, and electronics, where they support the operation of machinery and equipment by providing the necessary voltage levels.

- In summary, normal transformers are essential devices in electrical engineering, characterized by their ability to efficiently manage voltage levels, their robust design, and their critical role in both power distribution and industrial applications. Their specifications, including power rating, efficiency, and operational frequency, are tailored to meet the diverse needs of modern electrical systems.

Exploring Current Transformers (CT)

- Current Transformers (CTs) are specialized devices used to measure and monitor electrical current in power systems. Unlike normal transformers, which primarily function to transfer electrical energy between circuits, CTs are designed to provide an accurate representation of the current flowing through a conductor. They achieve this by scaling down high currents to a lower, manageable level, which can then be safely measured and analyzed.

- The design of a current transformer differs significantly from that of a normal transformer. A CT typically consists of a primary winding, which is connected in series with the conductor carrying the high current, and a secondary winding, which produces a scaled-down current proportional to the primary current. This secondary current is then used for various applications such as protection and metering. The core material and winding configuration of CTs are optimized to ensure high accuracy and reliability in current measurement.

- CTs play a crucial role in the protection and metering of electrical systems. In protection applications, they provide accurate current measurements to relay protection systems, which are essential for detecting faults and triggering protective measures to prevent damage to the electrical infrastructure. In metering applications, CTs are used to measure electrical energy consumption accurately, which is vital for energy management and billing purposes.

- When selecting a current transformer, several key specifications and ratings must be considered. The accuracy class of a CT indicates its measurement precision and is critical for applications requiring high accuracy. The burden, which refers to the load connected to the secondary winding, affects the CT’s performance and must be within specified limits to ensure accurate measurements. The rated secondary current, typically 1A or 5A, defines the standard output current for a given primary current.

- In conclusion, current transformers are indispensable components in electrical systems, providing precise current measurements for protection and metering purposes. Understanding their design, applications, and key specifications is essential for optimizing their performance and ensuring the reliability of electrical infrastructure.

Key Differences Between CT and Normal Transformers

- Current Transformers (CTs) and normal transformers serve distinct purposes within electrical systems, and understanding their differences is crucial for their appropriate application. While normal transformers are primarily designed for voltage transformation, converting voltages from one level to another to facilitate power distribution and transmission, CTs are specialized devices focused on measuring electrical current without directly interfering with the high-voltage circuit.

- The primary function of a normal transformer is to step up or step down voltage levels, ensuring efficient power distribution across long distances. These transformers are integral to the power grid, enabling the transfer of electricity with minimal losses. In contrast, CTs are used predominantly in metering and protection systems. They provide a scaled-down replica of the current in a high-voltage line, which can be safely monitored and measured by instruments and protective relays.

- Design differences are also notable between the two types of transformers. Normal transformers typically have a core and windings designed to handle high power levels, ensuring efficient energy transfer. They are built to endure the thermal and mechanical stresses associated with high-voltage operations. Conversely, CTs are designed to maintain accuracy in current measurement over a range of operating conditions. They feature a core and secondary winding tailored to produce an accurate, reduced current that reflects the primary circuit’s current.

- Operational characteristics further differentiate these transformers. Normal transformers operate continuously, transferring power efficiently across varied load conditions. CTs, however, are designed to operate within specific accuracy classes, ensuring precise current measurement critical for system protection and monitoring.

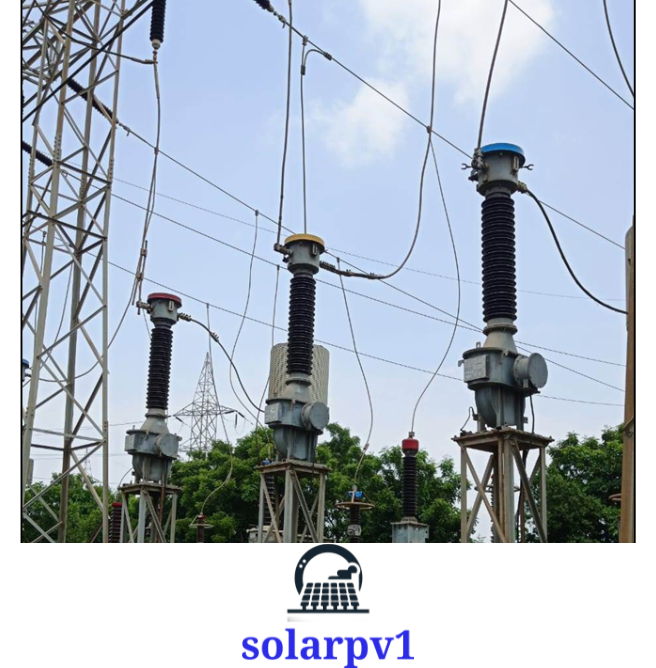

- The typical installation environments for these transformers also vary. Normal transformers are commonly found in substations, industrial facilities, and residential areas as part of the power distribution network. CTs are installed in locations where current measurement is essential, such as substation metering panels, relay protection circuits, and in industrial automation systems.

- Electrical safety and system management roles also differ. Normal transformers ensure voltage levels are appropriate for safe power distribution and end-use. CTs enhance safety by enabling accurate current measurement, which is essential for protective devices to function correctly, preventing overcurrent and potential system failures.

- In summary, while normal transformers are vital for voltage conversion and power distribution, CTs are crucial for accurate current measurement and electrical system protection. Each type has its advantages and limitations, making their selection dependent on the specific requirements of the electrical system in question.